Now that ULSD is the dominant diesel fuel being produced, many questions and concerns have surfaced.

By Jim Brightly, F358406, Technical Editor

April 2008

Editor’s note: This article was updated April 15, 2009, to incorporate corrections not contained in the original print magazine version.

If the letters we’ve received in the past year or so are any indication, most of you already know that any diesel engine manufactured after January 1, 2007, must use ultra-low-sulfur diesel (ULSD) fuel. In addition, diesel fuel suppliers and stations “” truck stops, service stations, discount houses “” in the United States and Canada have begun the transition to ULSD fuel.

In California, retail outlets selling diesel fuel for highway use had to convert to 100 percent ULSD by September 1, 2006. In other states, all highway diesel fuel sold at retail outlets must be ULSD by December 1, 2010. (Canada has aligned its requirements with the U.S. compliance dates; Mexico is expected to begin its transition in 2008.)

The reason for this mandate from the United States Environmental Protection Agency (EPA) and Canada’s ministry is an effort to reduce airborne contaminants caused by the presence of sulfur in diesel fuel. The newer engine designs use, among other devices, catalytic converters and more sophisticated exhaust gas recirculation (EGR) systems. Higher levels of sulfur reduce the catalytic converter’s ability to scrub the engine’s exhaust gases. In other words, the lower the sulfur content, the longer the catalytic converter lives.![]()

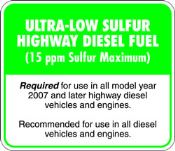

As of June 1, 2006, each diesel station’s pump (except those in California “” they had to begin labeling pumps much earlier) was required to have a label that correctly identified the type of diesel fuel being sold from that pump “” low-sulfur diesel (LSD) or ULSD.

This requirement raised concerns by owners of pre-2007-model-year engines, and letters and e-mails started to arrive at FMCA headquarters as members began seeing the new labels at the pump islands. ULSD’s lubricity and its possible effect on engine seals were members’ major concerns. We hope this article puts these concerns to rest.

Please note that diesel fuel classified as low-sulfur diesel (LSD) may still be sold at retail locations outside of California until December 1, 2010. Therefore, until that date, if your coach requires ULSD, you must check the pump’s label, and check it carefully. Also, although ULSD is the dominant fuel currently being sold, the Environmental Protection Agency does not require service stations and truck stops to sell ULSD, so it might not be available at every location.

According to the Flying J Web site (www.flyingj.com/fuel/diesel_CF.cfm), every Flying J fueling station listed carries ULSD, and the Web site provides up-to-date prices. The FMCA North American Road Atlas and Travel Guide flags all the Flying J sites.

The EPA requirement was restricted to engines built after January 1, 2007, and not chassis or motorhomes. You may actually have a 2007 “” or even 2008 “” model year motorhome and not have a 2007 engine. Chassis manufacturers have to pre-order a large number of engines for new chassis production. Once the chassis are assembled, they are transported to the motorhome manufacturers’ assembly plants, where they may sit for several months before entering the assembly line. Vehicles that require ULSD fuel have specific labels on the dashboard and near the fuel inlet indicating that they must be fueled with ULSD. To make sure, however, the owners can contact the motorhome manufacturer and provide the vehicle identification number (VIN) to verify the type of engine.

Will ULSD fuel affect the engine’s performance? Under typical operating conditions, using ULSD fuel should have no noticeable impact on overall power; however, fuel economy may be reduced slightly, because the process that removes sulfur also can reduce the energy content of the fuel. Engine and vehicle manufacturers tell us that ULSD is fully compatible with the existing fleet, including 2006 and earlier model year vehicles.

Even with these assurances, however, in some instances the introduction of ULSD fuel to older vehicles may affect fuel system components or loosen deposits in fuel tanks; so, if you have an older coach, you need to examine the entire fuel system for possible seepage or leaks. As you know, a leak in the fuel system can be dangerous, potentially causing a fire if diesel fuel comes in contact with hot engine parts. It is strongly recommended that you consult with the vehicle manufacturer for advice about maintaining or replacing the fuel system seals in your vehicle. And as part of a good maintenance program, you are highly encouraged to monitor your vehicle closely for potential fuel system leaks or premature fuel filter plugging.

Are additives needed to replace the lubricity that was provided by the higher sulfur content? Lubricity is a measure of the fuel’s ability to lubricate and protect the various parts of the engine’s fuel injection system from undue wear. The processing required to reduce sulfur to 15 parts per million also removes naturally occurring lubricity agents in diesel fuel. ULSD requires the addition of good lubricity and corrosion inhibitors to prevent unacceptable engine wear. These additives are mixed in ULSD fuel prior to its retail sale. To manage this change, the American Society for Testing and Materials (ASTM) adopted the lubricity specification defined in ASTM D975 for all diesel fuels; this standard went into effect January 1, 2005. No post-retail additives are needed or required.

Can ULSD cause premature fuel pump failure in earlier model engines? The original formulation of petroleum diesel caused pump seals to swell, and biodiesel swells seals even more. Untreated ULSD, with its reduced sulfur content, can cause the seals to shrink and harden. Too many changes can damage the seals, and the pump will leak fuel and/or suck in air. However, it must be said that most of the failures occurred in engines that ran on different types of fuel. Injector pump seals that are only exposed to two types of fuel, biodiesel and ULSD, are apparently not failing. (Please see the sidebar for information about biodiesel.)

According to the Clean Diesel Fuel Alliance “” an industry group consisting of oil and gas producers, engine manufacturers, the American Petroleum Institute (API), and others “” engine and vehicle manufacturers are not anticipating that owners of existing diesel engines will have to make changes to their equipment to operate on the new fuel.

How is the heavy-duty crankcase oil affected by ULSD? It depends. If you are running a pre-2007 engine, you can use the same API CI-4 Plus oil. However, if you have purchased a new coach “” 2007 or later “” equipped with an EGR engine with a diesel particulate filter, the required heavy-duty engine oil is API CJ-4 motor oil.

I hope this answers most of your questions about using ULSD fuel in your motorhome. The EPA states that these new regulations will significantly reduce nitrous oxide (NOx) and particulate matter emissions to the atmosphere. To attain these emission reductions, the EPA has established a comprehensive program to regulate diesel fuel along with the production of diesel engines. You can obtain additional information about ULSD at the EPA Web site (www.epa.gov/diesel/comphelp.htm) or by visiting www.clean-diesel.org.

What is biodiesel?

Biodiesel blends are mixtures of petroleum-based diesel fuels and fuels produced from soybean oil, waste cooking grease, or other organic matter. These fuels may contain biodiesel in concentrations ranging from 2 percent to levels approaching 100 percent by volume. To ensure proper quality, you should use only biodiesel-ULSD fuel blends that are properly mixed by a qualified biodiesel blender. Consumers should not create their own biodiesel blends by adding biodiesel to ULSD fuel in a vehicle’s fuel tank. There should be no operational problem if you switch from a biodiesel-ULSD fuel blend to ULSD fuel without biodiesel.

The major RV diesel engine manufacturers allow biodiesel blends provided that the biodiesel meets accepted (ASTM) fuel quality standards. Specifically, Cummins allows a concentration of up to 20 percent biodiesel, while Caterpillar and Detroit Diesel allow 5 percent blends. Biodiesel is sold blended with petroleum diesel. The percentage of biodiesel in the blend is designated by a number: B20 is 20 percent biodiesel and 80 percent petroleum diesel, B5 is 5 percent biodiesel, B100 is pure biodiesel.

Straight vegetable oil, which is nontoxic, is not the same as biodiesel. When people talk about converting a diesel engine, they usually are talking about the modifications needed to run it off of straight vegetable oil (SVO) or waste vegetable oil (WVO). In an SVO system, the oil is thinned by heating the fuel tank and/or fuel lines before it is sent to the fuel injectors. SVO systems have not been in use for as long as biodiesel and are still somewhat experimental. And none of the aforementioned engine manufacturers allow either type of vegetable oil in percentages greater than those listed above.

One benefit of biodiesel is that no conversion to a vehicle is needed. Biodiesel can be “splash blended” with ULSD at any time in the fuel tank; that is to say, B5 (or B20 in Cummins’ case) can be added to straight ULSD fuel in the fuel tank. Your driving will then mix the two, thereby resulting in a lower percentage.

Be cautious if using biodiesel in your vehicle, however. Most pre-1994 vehicles have non-biodiesel-compatible fuel lines (biodiesel will gradually degrade these fuel lines, causing them to become malleable, weepy, or spongy before they completely melt. Biodiesel will clean out your entire fuel system, so it may clog your fuel filter. In addition, biodiesel gels at around 32 degrees Fahrenheit or higher, depending on what kind of oils/fats it was made from (petroleum diesel fuel gels at around 10 degrees; however, this shouldn’t be a problem in a motorhome unless the fuel wasn’t stabilized prior to storage or cold weather).

Further information about the use of biodiesel can be found on the Web site of your engine manufacturer.