Having an onboard source of clean, dry air makes it a breeze to keep motorhome tires properly inflated.

By Mark Quasius, F333630

May 2016

It’s important to maintain the correct air pressure in motorhome tires. Neglecting that task can lead to overworked tires that may fail. However, when traveling it’s not always easy to find air for a large motorhome.

One option is to carry a portable electric air compressor, but that has disadvantages. For one, it takes up valuable storage space in a motorhome’s basement. And when plugged in, it consumes considerable electricity, which isn’t always available. Also, in order to run on a typical 120-volt circuit, such compressors have limited horsepower; as a result, they pump a fairly low volume of air, which increases the time needed to fill large tires.

Diesel motorhomes have an engine-driven compressor that powers the air brakes and air-ride suspension systems. Many such motorhomes also are equipped with an auxiliary air connection that can be used to fill tires or to operate small air tools. The engine-driven compressor pumps air at a higher volume than electric pancake-style compressors. And, all of the output passes through the air system’s filter-dryer so that the tires receive dry-filtered air.

To determine accurate tire inflation pressures, a motorhome should be weighed by individual wheel position when the coach is fully loaded. These readings can be compared with the tire manufacturer’s inflation pressure charts. The scale readings will verify the correct minimum tire pressures of your particular coach.

To determine accurate tire inflation pressures, a motorhome should be weighed by individual wheel position when the coach is fully loaded. These readings can be compared with the tire manufacturer’s inflation pressure charts. The scale readings will verify the correct minimum tire pressures of your particular coach.

Many large tag-axle diesel pushers may need to run in the neighborhood of 120 psi on the front-axle tires. The problem is that the engine-driven compressor may put out 125 psi at the high end but then drop to approximately 100 psi before the compressor’s governor tells it to resume pumping. Trying to squeeze those last few pounds per square inch into steer tires can be a challenging experience at best. One solution is to use an air-pressure booster.

How A Booster Works

A pressure booster functions much like an electrical transformer. A step-up transformer converts lower incoming voltage to higher voltage on the output side, trading off amperage for voltage. A pressure booster operates in a similar manner by trading volume of air (cubic feet per minute) for pressure.

Pressure boosters do not require electricity to function; they operate strictly by air pressure. Air from the compressor arrives at the booster’s intake port, where it fills the drive and pressure chambers. Internal valves direct the incoming air to the drive chamber and force the piston to one side; air in the chamber is compressed to a much higher pressure, and then directed to the output port. The system then reverses and drives the piston in the opposite direction to deliver a continuous stream of high-pressure air to the output port.

Pressure boosters are quieter than electric pancake compressors, do not create as much heat, and are very compact. They can be mounted in a small area, leaving more room for other cargo. Most pressure boosters are designed for industrial use and are basically maintenance-free. They will operate virtually forever in an RV.

My Selection

I was intrigued when I first saw a pressure booster at Bob Dickman Tire Center, a Junction City, Oregon, tire dealer that specializes in RVs. They put together a portable unit that was available in a hard-shell case from Pelican Products. However, I eventually chose an SMC Pneumatics pressure booster, because the compact module was a perfect fit for my permanently mounted application.

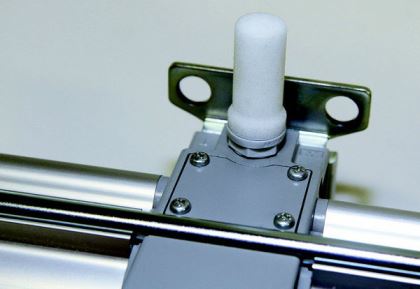

SMC Pneumatics makes a wide range of air-system components and offers an extensive selection of pressure boosters. I selected model VBA20A-T03GN-Z, which is designed for 3/8-inch air lines and is a good choice for the typical 18.7-cubic-feet-per-minute output of our coach. In mid-March 2016, the price was listed at $464.85 on the SMC Pneumatics website. Prices from other sources vary.

This model features a 2X pressure boost; so, to achieve 120 psi on the output side, I need only a minimum input of 60 psi. The unit is equipped with a regulator to limit output pressure so that I won’t put air at 200 psi into my air hose when the compressor is in the 100-psi range. I set the regulator at 140 psi, which was more than enough for my needs. This model came with a pair of pressure gauges, one to show incoming pressure and one to display outgoing pressure.

This model features a 2X pressure boost; so, to achieve 120 psi on the output side, I need only a minimum input of 60 psi. The unit is equipped with a regulator to limit output pressure so that I won’t put air at 200 psi into my air hose when the compressor is in the 100-psi range. I set the regulator at 140 psi, which was more than enough for my needs. This model came with a pair of pressure gauges, one to show incoming pressure and one to display outgoing pressure.

My Installation

My Entegra Cornerstone is equipped with three air connections. One is in the rear engine compartment, another is in the curbside basement compartment where the freezer is located, and the third is in the driver’s-side compartment just ahead of the large pass-through bays. I chose to install in the third location, because it would be easy to mount the pressure booster without intruding on storage space. It also is a good compartment for storing my 50-foot hose, which can easily reach any place on the coach from this location.

I decided to mount the booster onto a steel plate in order to spread out the vibration load on the carpeted plywood compartment wall. The unit must be mounted horizontally rather than vertically; this worked well, because I could place it up high so that it was out of the way, yet still visible.

I made a short whip hose with a male coupler plug to connect the booster to the motorhome’s existing quick-disconnect air coupling. That way, I could unplug the whip hose and bypass the pressure booster if necessary. I also created a short whip hose with a female coupler body and connected it to the booster’s output so that I wouldn’t have to reach all the way into the compartment to connect my 50-foot air hose. I screwed the included muffler into the exhaust port to minimize any noise from the drive piston’s air exhaust, set the air-pressure regulator to limit the outgoing air pressure, and fired up the coach’s engine.

Results

Results

The system works perfectly. I used to have to monitor the air pressure on a gauge that I attached via a tee. When the motorhome’s air pressure dropped below what I needed, I would bleed the air so the compressor would begin pumping again. Then I carefully monitored the pressure to make sure I stopped filling in time to catch it before it dropped again.

Now, with the pressure booster, I can skip that balancing act and easily fill my steer tires to the correct pressure. The booster ensures that I always have plenty of clean, filtered, and dry air. It’s now an effortless task that saves time.

More Info

Bob Dickman Tire Center

222 W. First Ave.

Junction City, OR 97448

(800) 257-8430

(541) 998-3319

www.dickmantires.com

SMC Pneumatics

3810 Prospect Ave., Unit A

Yorba Linda, CA 92886

(800) 660-0733

(714) 312-5419

www.smcpneumatics.com