When winterizing the RV, tasks include preparing the plumbing system in order to prevent freeze damage.

By Mark Quasius, F333630

November 2017

Winterizing the motorhome probably isn’t your favorite task, but it must be done. Unless, of course, you are lucky enough to head south before winter arrives, in which case you just pull the water hoses in when the nighttime temperature drops below freezing and put them out again when it warms up the next day. But for those of us stuck in northern climates, winterizing is necessary to protect the RV from freeze damage.

Winterizing deals primarily with the plumbing system. All water must be removed from holding tanks, water lines, and plumbing fixtures. Secondary tasks involve removing from the motorhome items such as perishable food, as well as cleaning and personal hygiene products that should not freeze. Also, this is a good time to thoroughly clean the RV and make it less enticing for mice.

Two methods are used to winterize RV plumbing. One relies on air pressure to blow moisture out of the system; the other pumps nontoxic RV antifreeze through water lines.

Using air has pros and cons. Air is easy to use; just connect an air compressor to the water hose and blow everything out. In theory, the system will be dry. Plus, air is free, so it eliminates the need to buy bottles of antifreeze. But air has a few drawbacks as well. Air pushes most of the water out, but residual water often remains in the lines. It can collect in a low spot in the lines where it can freeze, expand, and cause damage.

Using air has pros and cons. Air is easy to use; just connect an air compressor to the water hose and blow everything out. In theory, the system will be dry. Plus, air is free, so it eliminates the need to buy bottles of antifreeze. But air has a few drawbacks as well. Air pushes most of the water out, but residual water often remains in the lines. It can collect in a low spot in the lines where it can freeze, expand, and cause damage.

On a simple system with minimal plumbing lines, that may not be an issue. But on more complex systems, air may not be enough to prevent freeze damage. That’s why in my home state of Wisconsin, where winters are long and cold, RV dealers tend to use antifreeze.

Antifreeze is the best method for preventing freeze damage. In fact, Aqua-Hot calls for using antifreeze rather than air to ensure that water has been removed from the domestic hot water coils and valving in its hydronic heating systems. Antifreeze pushes water out of the system; any remaining water mixes with the antifreeze.

Antifreeze is the best method for preventing freeze damage. In fact, Aqua-Hot calls for using antifreeze rather than air to ensure that water has been removed from the domestic hot water coils and valving in its hydronic heating systems. Antifreeze pushes water out of the system; any remaining water mixes with the antifreeze.

RV antifreeze differs from automotive antifreeze. RV antifreeze is nontoxic and is safe to use in fresh-water systems. It freezes but does not solidify. Instead, it turns to slush, which will not expand and crack fittings or PEX water lines. One drawback to antifreeze is that it’s messier than using air and requires buying a few gallons every season. It also can cause water that runs through the PEX lines to taste bitter. To minimize this, blow the lines out with air initially, and then follow up with antifreeze. Once antifreeze has been thoroughly distributed throughout the system, reconnect the air compressor and blow it out; often a large portion can be recaptured and used to winterize the next year. Blowing out the antifreeze minimizes the water’s bitter taste. And, when dewinterizing the following spring, it won’t take as long to flush the system.

Begin the winterizing procedure by draining the holding tanks. Use the tank flushing tool or in-tank sprayer head to thoroughly clean the black tank and remove deposits that can harden or cause odors during storage. Use a clear sewer hose fitting so you know when the flush water is clear. Drain the fresh-water tank at the same time.

![]() If you have a tank-type water heater, drain the tank by removing the drain plug. Open the pressure-relief valve near the top of the heater to allow air to enter the top of the tank for a smoother drain through the lower drain port. Some water heaters, such as Suburban, have an anode rod to help ward off tank corrosion. Such rods generally are part of the drain plug, so if a rod is present, be sure to inspect it for erosion. The anode’s life span depends on the quality of water introduced into the coach. Given that such rods are inexpensive, I recommend replacing them every year. Some tanks, such as Atwood’s aluminum tanks, do not have anode rods and are equipped withnylon drain plugs. Use the correct replacement plug for your heater.

If you have a tank-type water heater, drain the tank by removing the drain plug. Open the pressure-relief valve near the top of the heater to allow air to enter the top of the tank for a smoother drain through the lower drain port. Some water heaters, such as Suburban, have an anode rod to help ward off tank corrosion. Such rods generally are part of the drain plug, so if a rod is present, be sure to inspect it for erosion. The anode’s life span depends on the quality of water introduced into the coach. Given that such rods are inexpensive, I recommend replacing them every year. Some tanks, such as Atwood’s aluminum tanks, do not have anode rods and are equipped withnylon drain plugs. Use the correct replacement plug for your heater.

Once the water heater tank is drained, switch off the 120-volt-AC circuit breaker that powers the water heater, if equipped with an electric element. It’s also a good idea to turn off the heater’s rocker switch (if so equipped) to prevent accidentally turning on the water heater’s electric heating element from inside the coach. The element will burn out if turned on when there is no water in the tank.

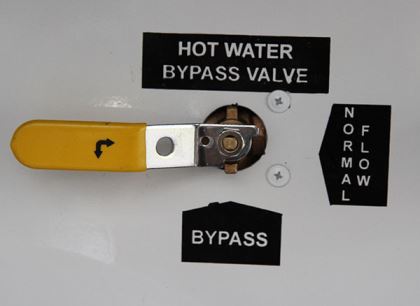

![]() Replace the drain plug and close the pressure-release safety valve. Then set the water heater bypass valve (or valves) to the bypass position. Depending on the RV, from one to three such valves cause incoming water to bypass the water heater tank and go directly through the hot water lines. Be sure to refer to the RV’s owners manual for the exact procedure. Failure to bypass the water heater wastes money by pumping lots of antifreeze into the heater tank.

Replace the drain plug and close the pressure-release safety valve. Then set the water heater bypass valve (or valves) to the bypass position. Depending on the RV, from one to three such valves cause incoming water to bypass the water heater tank and go directly through the hot water lines. Be sure to refer to the RV’s owners manual for the exact procedure. Failure to bypass the water heater wastes money by pumping lots of antifreeze into the heater tank.

Low-point drain valves — one for the cold-water lines and one for the hot-water lines — generally are located in the bottom of the basement utility compartment. Although the valves are supposed to be positioned at the RV’s lowest point, that doesn’t ensure all the water will drain out. It must be removed with air pressure or antifreeze after the tanks have fully drained.

To use air to blow water from the system, connect an air compressor to the incoming fresh-water connection on the RV. If the RV has a hose reel, blow it out also. Use a pressure regulator and adjust it so that the air pressure is between 20 and 30 psi. Excessive pressure may cause a blast of water to spray in your face when you open up a sink faucet, or fittings or tubing may be damaged.

Simple blow-out adapters are available at RV accessory outlets, but they require holding a tire chuck onto the fitting, which can get tedious after a while. The adapters also require an assistant. An alternative: Visit a home-improvement or auto-parts store and buy a small pressure regulator with a gauge, a male garden hose fitting, and a coupler plug that fits your air compressor’s hose. This will make it much easier to blow out the system.

Simple blow-out adapters are available at RV accessory outlets, but they require holding a tire chuck onto the fitting, which can get tedious after a while. The adapters also require an assistant. An alternative: Visit a home-improvement or auto-parts store and buy a small pressure regulator with a gauge, a male garden hose fitting, and a coupler plug that fits your air compressor’s hose. This will make it much easier to blow out the system.

Begin by opening the hot-water and cold-water faucets inside and outside the coach. Open the sink and shower faucets and close them once the water has been blown clear. Flush the toilet in the same manner. Blow out the drinking water and refrigerator water dispenser, if so equipped. Once finished, open the low-point drains once again to allow water to exit, and then open the dump valves for the black tank and gray tank to remove water that entered during the blow-out process.

This is also the time to remove the filter element from the motorhome’s water filter. The RV may have multiple filters, including one for the drinking-water dispenser in the galley. And don’t forget about the refrigerator. If it has an in-door water dispenser and/or ice maker, there may be a filter in the refrigerator itself. Remove and discard the filters, replacing them with bypass tubes or plugs.

Dishwashers, laundry centers, and hydronic heating systems require more than air to ensure adequate protection against freezing, so it’s now time to step up to antifreeze.

Once most of the water has been blown out, drop an antifreeze pickup hose into a jug of RV antifreeze. Because a gallon of antifreeze doesn’t go very far on a large motorhome, my preference is to fill a clean 5-gallon bucket with several jugs of antifreeze and then insert the hose into the bucket to prevent running dry periodically.

![]() Open the winterization valve to allow the water pump to suck the antifreeze from the bucket rather than from the fresh-water tank. If there is no winterization valve, disconnect the inlet line from the fresh-water tank to the water pump and install the antifreeze pickup hose. Be sure all faucets and fixtures are turned off before turning on the water pump.

Open the winterization valve to allow the water pump to suck the antifreeze from the bucket rather than from the fresh-water tank. If there is no winterization valve, disconnect the inlet line from the fresh-water tank to the water pump and install the antifreeze pickup hose. Be sure all faucets and fixtures are turned off before turning on the water pump.

Turn on the water pump. You should hear it run and cycle until it builds up pressure in the line. The first thing I do is open the run/fill valve to the tank fill position. I hold it open for a few seconds to put a small amount of antifreeze in the fresh tank, and then I close the valve. This ensures that the line that feeds the tank is free of water. It also allows a bit of antifreeze to settle into the tank, where it can protect the tank drain line. I then open the water heater bypass valve for a second or two, which ensures all the water is out of the short lines between the valve and tank.

Next, rotate through the motorhome’s sinks and shower and open each fixture’s cold-water faucet, one at a time, until antifreeze comes out. Start with the fixture farthest from the water pump and work back toward the pump, so that the longest fluid runs are the first to be filled with antifreeze. Then repeat for the hot-water faucet. Do the outside shower in the same manner.

I keep an eye on the antifreeze level in my 5-gallon bucket so I’m ready to add more if needed. Antifreeze usage will vary by RV. Some simple systems may get by with only 3 gallons, while larger coaches with hydronic heating systems, full laundry centers, dishwashers, and bath-and-a-half layouts will require much more. You may be able to recover a large portion of it for use next year.

Once the sinks and shower are finished, pour a bitof antifreeze into the drains to seal and freeze-proof the P-traps and prevent gray-tank odors or sewer gas from wafting into the motorhome. Do this even if only air is used to blow out the system. Next, flush the toilet until you see antifreeze coming into the bowl. Keep a small amount in the bowl to prevent the seal from drying out while in storage.

A few extra steps must be performed in motorhomes equipped with a hydronic heating system, dishwasher, or laundry center. Hydronic heating systems such as ![]() Aqua-Hot and Oasis provide unlimited on-demand hot water by running cold water through a heat-exchanger coil inside the boiler. The hot water also passes through a tempering valve as it exits the boiler. To ensure that all water is purged from the system, antifreeze must be pumped through the system until it is seen exiting a hot-water faucet on one of the sinks. Simply blowing out such systems with air is not recommended; freeze damage can result in very expensive repairs. Once the hydronic heating system is winterized, the burner can still be operated to provide heat for the RV without damaging the system.

Aqua-Hot and Oasis provide unlimited on-demand hot water by running cold water through a heat-exchanger coil inside the boiler. The hot water also passes through a tempering valve as it exits the boiler. To ensure that all water is purged from the system, antifreeze must be pumped through the system until it is seen exiting a hot-water faucet on one of the sinks. Simply blowing out such systems with air is not recommended; freeze damage can result in very expensive repairs. Once the hydronic heating system is winterized, the burner can still be operated to provide heat for the RV without damaging the system.

![]() If you have a laundry center, start a wash cycle to pump antifreeze into the washer’s drum. Use a warm-water setting so that both the hot-water and cold-water lines are purged. Once antifreeze begins to fill in the drum, stop the cycle. Then dial the washer control to the spin cycle and turn it back on. The drain valve will open as the drum spins, and the antifreeze will exit the drum and pass through traps. Refer to the washer’s owners manual for the exact procedure.

If you have a laundry center, start a wash cycle to pump antifreeze into the washer’s drum. Use a warm-water setting so that both the hot-water and cold-water lines are purged. Once antifreeze begins to fill in the drum, stop the cycle. Then dial the washer control to the spin cycle and turn it back on. The drain valve will open as the drum spins, and the antifreeze will exit the drum and pass through traps. Refer to the washer’s owners manual for the exact procedure.

The process is similar for a drawer-style dishwasher. Begin a cycle to fill the drawer, and then pause the cycle once you hear the antifreeze spraying in the drawer. Open the drawer; antifreeze should be puddling in the bottom. Close the drawer and cancel the cycle. The drain pump will engage and antifreeze will drain from the drawer and pass through the drain lines.

![]() The water-supply line of refrigerators equipped with ice makers also must be protected. On the back of the refrigerator is a water solenoid, which typically is connected to a 120-volt receptacle. Remove the hose from the solenoid valve and let it dangle behind the fridge. Sometimes this will drain water from the line, but water might still be in the mechanism.

The water-supply line of refrigerators equipped with ice makers also must be protected. On the back of the refrigerator is a water solenoid, which typically is connected to a 120-volt receptacle. Remove the hose from the solenoid valve and let it dangle behind the fridge. Sometimes this will drain water from the line, but water might still be in the mechanism.

![]() Electricity poses an electrocution hazard, so attempt the following only if you have adequate knowledge and tools. Disconnect the wires from the solenoid and connect a power cord with female spade terminals to the solenoid. If the refrigerator has a 120-volt solenoid, plug the cord into a receptacle, which will open the solenoid valve so that air or antifreeze can pass through the system. If you have a 12-volt solenoid, connect it to a 12-volt power source. This should purge water through the ice maker. Use air, rather than antifreeze, for the initial blow-out process. Once blown clear, to prevent antifreeze from entering the refrigerator’s water line, close the petcock that usually is located in the basement beneath the refrigerator. Place a towel in the freezer to catch water spray that leaves the ice maker.

Electricity poses an electrocution hazard, so attempt the following only if you have adequate knowledge and tools. Disconnect the wires from the solenoid and connect a power cord with female spade terminals to the solenoid. If the refrigerator has a 120-volt solenoid, plug the cord into a receptacle, which will open the solenoid valve so that air or antifreeze can pass through the system. If you have a 12-volt solenoid, connect it to a 12-volt power source. This should purge water through the ice maker. Use air, rather than antifreeze, for the initial blow-out process. Once blown clear, to prevent antifreeze from entering the refrigerator’s water line, close the petcock that usually is located in the basement beneath the refrigerator. Place a towel in the freezer to catch water spray that leaves the ice maker.

Most refrigerators have a way to cycle the ice maker manually. You can do this while the system is under air pressure. It takes a few cycles to completely purge all of the water from the system. Once finished, close the petcock to seal off that line before pumping antifreeze through the rest of the system. If you have a residential fridge with an in-the-door water dispenser, run lots of air through that in order to empty the bladder inside the fridge. It’s also possible to cycle the fridge while pumping antifreeze and run it until pink ice cubes appear in the bin. However, more antifreeze will be required, and it will take a while to remove the antifreeze taste next spring when you dewinterize.

One of my last steps is to remove antifreeze from the plumbing, although this isn’t really necessary as long as all of the water has been forced out of the system. I reconnect the air hose, blow the antifreeze out, and recapture quite a bit via the low-point drains so that it can be reused next year. Removing the antifreeze also minimizes the bitterness I’ll taste after filling the fresh-water tank in the spring.

I make sure enough antifreeze has passed through the shower and sinks to leave a fair amount in each trap, which prevents gases from backing up into the coach. If in doubt, I’ll pour a cup or two into each drain. Then I drain the excess antifreeze from the holding tanks and put my sewer hoses away.

I make sure enough antifreeze has passed through the shower and sinks to leave a fair amount in each trap, which prevents gases from backing up into the coach. If in doubt, I’ll pour a cup or two into each drain. Then I drain the excess antifreeze from the holding tanks and put my sewer hoses away.

With the plumbing system ready for winter, attention turns to other areas. This is a good time to change the engine oil and service the various chassis lubrication points. Acidic contaminants in the oil can eat away at the engine and cause pitting; changing the oil now ensures that this won’t happen and means there will be one less thing to do next spring when you are itching to travel.

With the plumbing system ready for winter, attention turns to other areas. This is a good time to change the engine oil and service the various chassis lubrication points. Acidic contaminants in the oil can eat away at the engine and cause pitting; changing the oil now ensures that this won’t happen and means there will be one less thing to do next spring when you are itching to travel.

Check tire pressures and inflate them to the maximum listed on the sidewall. Protect the tires from ultraviolet rays and ensure that no electric motors (which produce ozone) are nearby. Wash the tires with the same soap and similar washcloth as used on the motorhome exterior. To prevent flat spotting, remove some weight from the tires by lowering the leveling jacks. To help ensure that tires parked on concrete or asphalt don’t dry out, place a barrier beneath them to prevent wicking of the tires’ natural lubricants. Plastic, plywood, or rubber floor mats may be used for this purpose.

Clean the RV’s interior and exterior while the dirt is still relatively fresh. Keeping the exterior clean will prevent contaminants from eating into the finish. Remove cleaning materials or supplies that might freeze. Also remove anything that might attract mice.

Winterizing the motorhome can be a disheartening task, because for many it signals that camping season has ended. But once the job is done, you’re free to dream about where your travels will take you when warm weather returns.