An explanation regarding engine-related regulations designed to protect the environment and how they have impacted RV owners.

By Mark Quasius, F333630

May 2023

Vehicle exhaust emissions have changed drastically within the past 50 years. To reduce smog and pollution, the Environmental Protection Agency (EPA) gradually has implemented increasingly stringent regulations pertaining to vehicle emissions. These have included everything from requiring unleaded gasoline and catalytic converters to changes that led to today’s clean-burning diesel engines. The result is noticeable, with additional benefits of enhanced fuel economy and increased engine longevity. These improvements were possible largely because of greater use of intelligent electronic components, such as electronic control modules and various sensors on these engines.

Some fuel stations offer pump DEF, with the nozzle stored behind a rubber flap.

The first major revision came with the EPA 2007 regulations, which began to show up in diesel-powered motorhomes during the 2008 model year. These directives reduced particulate matter limits from 0.10 to 0.01 parts per million (ppm) and oxides of nitrogen (NOx) emissions from 2.5 grams per brake horsepower-hour down to 1.2 grams per brake horsepower-hour.

These regulations prompted the use of diesel particulate filters to remove soot from the exhaust. To reduce emissions and avoid damage to these filters, ultra-low-sulfur diesel fuel (ULSD) was required. ULSD reduced the 500-ppm sulfur content of low-sulfur diesel fuel to no more than 15 ppm. If the diesel particulate filter did become restricted by soot, the engine would need a regeneration cycle, which ran the engine at high speeds to burn off any accumulated soot. Normally, this wasn’t required; however, if the engine was left idling for extensive periods, regeneration could become necessary. Engine oils also had to be upgraded to the American Petroleum Institute (API) CJ-4 specification, which removed zinc from the oil, as it would damage the diesel particulate filter. As far as owners went, all they needed to do was make sure to use ULSD fuel and the proper CJ-4 engine oil, and to avoid excessive engine idling.

DEF is also available in plastic containers, such as this SuperTech brand from Walmart.

The EPA 2010 regulations were the next step. The impact of these regulations showed up in 2011 model-year coaches for the most part. The soot specification remained the same, at 0.01 ppm, so the diesel particulate filter itself did not have to change. However, the NOx requirement dropped significantly, from 1.2 grams per brake horsepower-hour all the way down to 0.2 grams per brake horsepower-hour. This required a new way of thinking to meet that specification.

Initially, Cummins chose the selective catalyst reduction (SCR) method to comply with those emissions requirements, while Navistar placed its bets on an advanced exhaust gas recirculation process to achieve results. The latter method was short-lived, however, as the advanced exhaust gas recirculation system generated a tremendous amount of heat that the engine couldn’t handle. So, the Cummins SCR system became the system of choice and was widely used on diesel-powered motorhomes as of 2011. The biggest change for owners was the need to deal with a new element commonly known as DEF, which stands for diesel exhaust fluid.

The SCR system adds a decomposition reactor where DEF is injected into the exhaust stream after the diesel particulate filter. First, the diesel particulate filter serves as both a filter and a catalyst that removes soot from the exhaust, trapping it in a wall-flow filter. At the same time, nitric oxide in the exhaust gas is then converted to nitrogen dioxide in the diesel oxidation catalyst. As the nitrogen dioxide flows through the wall-flow filter, it reacts with the carbon to produce carbon dioxide. The exhaust flow then exits the diesel particulate filter and enters the SCR decomposition chamber, where a dosing valve injects DEF into that chamber. Through a series of chemical reactions, ammonia vapor forms. Together, the NOx and ammonia pass from the decomposition reactor to the SCR catalyst chamber; there, they react to form nitrogen and water vapor. The end result is exhaust with near-zero emission levels.

SCR is after-treatment technology, so it destroys these harmful emissions following combustion, which gives the manufacturer the ability to fine-tune their engines to pro-duce maximum power, efficiency, and fuel economy.

DEF is a product designed exclusively for use in diesel engines that employ SCR emissions technology and is a non-hazardous solution of 32.5 percent urea and 67.5 percent deionized water. It’s clear and colorless. Engine manufacturers specify the use of DEF certified by the American Petroleum Institute (API), the same organization that rates engine oils and other petroleum products. The American Petroleum Institute has a Diesel Exhaust Fluid Certification Program that allows DEF producers to display the API-certified label on their DEF packaging if they comply with the ISO 22241 standard.

The Cummins aftertreatment system uses the selective catalyst reduction (SCR) method and incorporates a diesel particulate filter (DPF).

The SCR system is sensitive. Contaminated fluid can damage SCR injectors and catalysts, and strict tolerances limit the level of impurities in API-certified DEF. So, diesel owners should not use anything other than certified DEF with the API label.

The ISO 22241 standard ensures that DEF is produced with an exacting 32.5 percent urea concentration. This concentration was selected because it offers the lowest freezing temperature for DEF, 12 degrees Fahrenheit. Even the containers are regulated by ISO 22241. DEF is corrosive to carbon steel, copper, and aluminum, so containers made from these materials cannot be used. If your DEF container bears the API DEF certification mark, you can be assured that the product meets the ISO 22241 standard and is safe to use.

DEF usage will vary between vehicles. A common statement is that DEF usage will equal 2 percent of fuel consumption, but this is a generalization. A smaller and lighter motorhome may use only 1.5 percent if driven leisurely, while a larger coach with a 15-liter engine may consume as much as 4 percent if towing or working hard in the mountains.

Bulk DEF is available at truck stops from dedicated DEF pumps located on the driver’s-side fuel island, often right next to the diesel fuel pump and located behind a rubber flap. DEF also is available in 2.5-gallon containers at auto parts stores; fuel stations; and most large retailers, such as Walmart.

Because it is 67.5 percent deionized water, DEF can evaporate if stored at high temperatures for prolonged periods; however, field tests have shown that there isn’t a significant risk of evaporation from DEF tanks if you keep the container securely closed. DEF does have a shelf life of two years, but this can be reduced if the DEF is exposed to direct sunlight or if the temperature remains above 86 degrees Fahrenheit for sustained periods. DEF packaging does have an expiration date, so keep that in mind if you plan on stocking up on DEF. Ideally, your DEF should be stored in a location where temperatures do not drop below freezing or exceed 85 degrees, and it should be consumed within one year of purchase.

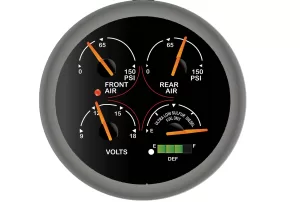

Instrument panels on vehicles that use DEF have a fluid level indicator, such as these green bars.

DEF must be stored in its own tank and should never be put into a diesel fuel tank; nor should diesel fuel ever be put into a DEF tank. Fortunately, a few safeguards exist to prevent this from happening. Diesel fuel nozzles are 0.87-inch (22 millimeters) in diameter, while DEF nozzles measure 0.75-inch (19 millimeters) in diameter. This should prevent anyone from accidentally inserting a diesel fuel pump nozzle into a DEF tank. Also, DEF tank caps are blue to distinguish them from diesel fuel tank caps.

Diesel fuel is lighter than DEF and will float on top of the DEF if it gets into the tank; however, even a small amount of diesel fuel will damage the SCR system, so if this happens, do not run the engine. Instead, call a service center immediately; do not drive the vehicle until they remove the diesel fuel from the DEF tank.

On the other hand, it is possible to insert the smaller DEF nozzle into a diesel fuel filler neck. Again, if this happens, do not start the engine. DEF contains 67.5 percent water, and this can have disastrous effects if mixed with diesel fuel, including exploding fuel-injector tips. Do not drive the vehicle; call for help to have the fuel system drained or cleaned to remove the DEF.

Some bulk DEF pumps have magnetic switches built into the nozzle. The DEF tank has a magnet in the filler neck that allows the DEF nozzle to open and dispense DEF. The nozzle will not allow any flow without that magnet, such as when inserting the DEF nozzle into a fuel tank filler. However, not every DEF pump has these magnetic switches, and neither do the 2.5-gallon jugs, so you need to pay attention to which tank you are adding DEF.

DEF is not hazardous, but it can stain clothes. If you spill some on your clothing, quickly wash it with water. If you spill a small amount on the ground, just rinse it with water or wipe it up with a paper towel or rag. Any residue that remains will turn to crystals, which also can be rinsed away with water. As mentioned earlier, DEF can be corrosive to carbon steel, copper, or aluminum; so, if those materials come into contact with DEF, rinse them off.

Because DEF corrodes certain metals, DEF tanks are made of polypropylene. Limits exist as to the length of the hoses that connect the DEF tank to the engine’s emissions systems, so you’ll find the tank located at the rear of the coach on a diesel-pusher chassis or at the front on a front-engine vehicle such as a Super C or Sprinter chassis. Most side-radiator chassis don’t have room for the DEF tank on the driver’s side of the coach, so the tank will be located on the curb side.

To accommodate the driver’s-side DEF tanks on large trucks, the DEF pump at truck stops is always on the driver’s side. This doesn’t always work well for a motorhome. Chassis manufacturers have made an effort recently to add driver’s-side DEF fills to make it more convenient for motorhome owners to use a DEF pump when refueling.

As noted earlier, DEF freezes at 12 degrees Fahrenheit. In cold temperatures, the DEF will not flow until it is warmed sufficiently. To assist with that, the engine cooling system passes heated coolant through a heating element in the DEF tank. The DEF begins to flow relatively quickly, and the emissions controls allow enough time for this to happen and do not issue any warnings.

The Cummins-brand DEF filter includes a small tool to help remove the filter from the housing.

When you shut down the engine, you may hear an electric pump running at the rear of the coach for approximately 60 seconds. The pump drains all the DEF from the hoses and returns it to the tank to prevent damage to the lines and valves from freezing. DEF expands about 7 percent when frozen, so you need to keep a bit of air space above the DEF in the tank to allow for expansion during cold weather. The filler neck in DEF tanks generally is low enough to prevent overfilling.

DEF is a critical element, and without it your emissions system will not work. The EPA requires that the vehicle emissions system be fully operational at all times, so certain safeguards have been put in place to ensure that you cannot continue to operate the vehicle without DEF. A gauge on the instrument panel helps drivers to monitor the DEF level in the tank. In most cases, this is a series of four LED bars built into the diesel-fuel gauge. Four green bars appear when the DEF tank is full. Three green bars indicate three-quarters full, two green bars indicate half full, and one green bar indicates one-quarter full. Generally, once the level of DEF in the tank reaches 10 percent, that last green bar will turn to amber. The LCD information center on the instrument panel will display a “LOW DEF” alert in addition to a warning icon. The vehicle will continue to operate normally, but more DEF should be added as soon as possible.

If you travel on without adding any, the amber LED bar will turn red when the DEF level in the tank reaches 5 percent. The information center will then display “ENGINE PERFORMANCE DERATE IMMINENT.” You now have very little time left to add DEF before your engine derates. Once the level drops to 3 percent, the display changes to “ENGINE PERFORMANCE DERATE ACTIVATED,” and your engine will be derated, with a 25 percent reduction in its torque output. You’ll still be able to limp off the road at reduced power, but you’ll be burning DEF as you do, and the next step is the final step.

Once the DEF tank gets down to 0 percent, the red LED bar remains illuminated, and the information center displays “SPEED RESTRICTION ON. DEF REQUIRED.” Engine torque will be limited to 60 percent, and the vehicle speed will be restricted to 5 mph. That’s enough to pull off to the side of the road, but you will need to fill the DEF tank to at least 10 percent of the tank capacity in order to drive to a location where you can top off the tank. Therefore, it’s wise to carry a 2.5-gallon jug or two of DEF as a safety precaution, even if you normally refill with pump DEF at truck stops.

In addition to the DEF-level sensing, derating, and shutdown monitoring, the EPA has added another requirement. Beginning around 2017, the EPA mandated new sensors that detect the quality of the DEF to prevent anyone from diluting it or using old DEF that no longer has the required percentage of 32.5 percent urea. When first introduced, these sensors proved to be quite temperamental, particularly on coaches equipped with Shaw sensors. These sensors would fail suddenly, stranding drivers on the side of the road. The sensors are located on the top of the DEF tank, and it seems that heat was the biggest culprit, causing the circuit boards to fail. Several temporary fixes have been used to combat these issues, including some homemade third-party DEF sensor bypass boards that allow the coach to continue operating until a new DEF sensor can be found. After a few years of trial and error, the latest iteration of sensors appears to be holding up.

The EPA has proposed new regulations that allow the driver more time until derating and shutdown occur, but these won’t take effect until 2027, and they won’t help anyone with a current coach (2017 and newer) that experiences a DEF sensor failure.

DEF systems aren’t high maintenance, but if you store your coach for a long time or run the engine for very short and infrequent periods, the DEF can become old and exceed its shelf life. In those instances, the best practice is to drain the DEF

from the tank and replace it with fresh every year.

Also, near the bottom of the DEF tank is a filter that should be replaced every 200,000 miles or two years, whichever comes first. The filter is easily removed with an 11/16-inch 12-point socket wrench and extension. In some cases, you may be able to remove the DEF filter cap with multigrip slip-joint pliers (such as Channellock brand), but if the cap is tight, you might damage it. The filter is at the base of the tank, so you’ll be looking up at it. Just be sure that you are off to one side when you remove it, because a bit of DEF will dribble out of the filter housing. The Cummins-brand DEF filter is a small cartridge that comes with a small tool to help yank the filter out of the housing. It is important that owners not neglect this filter when servicing the chassis. A plugged or restricted filter can lead to a failed DEF pump, which is an expensive repair.

EPA emissions regulations have brought about some very clean-burning diesel engines that are more economical and efficient than their predecessors. Other than having to refill DEF tanks and change a filter biannually, the impact on owners has been minimal. Overall, the changes have been good for the environment and for RV owners.