Swapping out solid axles on larger travel trailers for MORryde’s Independent Suspension softens the ride for everything inside.

By Bruce W. Smith

September 2023

Travel trailers and fifth-wheels take a pounding while being towed over the highways and byways of North America — and so does everything inside. Potholes, rough pavement, expansion joints, country roads, and entering and exiting parking lots and fuel stations all vibrate and shake the trailer.

The typical RV trailer leaf-spring suspension has only about two inches of total travel — less when it’s fully loaded.

Unlike the pickup doing the towing, the typical RV trailer leaf-spring suspension has only about two inches of total travel — less when it’s fully loaded. That makes it difficult for the trailer’s suspension to soften the impacts its wheels encounter as they roll down the road.

“That’s why we developed our Independent Suspension (IS),” said Jack Enfield, sales and marketing manager at MORryde, an industry leader in RV suspension systems. Jack is an avid RVer himself. “Our IS system provides more than five inches of suspension travel, which significantly reduces road shock and the damage it does to the trailer and its contents. The rubber shear springs in our IS system also reduce road-induced vibration, which also takes its toll on everything inside the trailer.”

It takes about 30 hours of labor to convert a tandem-axle RV trailer with leaf springs to the MORryde Independent Suspension.

RV ROAD SHOCK

Anyone who tows a trailer knows how road shock and vibration affect it. Cabinet doors coming open, broken items inside cupboards, screws and bolts backing out, loose TV mounts, and cabinets and countertops separating are all signs of impact encountered during towing.

“We’ve heard all kinds of extremes,” Enfield said. “On rear-kitchen fifth-wheels with leaf-spring axles, customers have complained they find broken things all over the place. You feel the road shock in the truck going over a bridge, an expansion joint, crossing rail-road tracks, hitting a chuckhole, then you feel it all again when the trailer makes contact.”

More than a dozen preinstallation/preorder measurements are taken when the initial appointment is made. Each MORryde conversion axle assembly is custom made.

With each impact, large or small, the G-forces are transmitted upward from the tires through the leaf springs and into the trailer body. As the road miles add up, so does the road shock damage, seen and unseen, inside the trailer.

SOFTENING THE RIDE

Elkhart, Indiana-based MORryde introduced the RV world to their independent trailer suspension in the mid-1990s. And now, factory-installed MORryde IS systems are standard beneath many of today’s high-end travel trailers and fifth-wheels.

According to Tommy Henderson, research and development manager at Henderson’s Line-up, Brake & RV/SuperSteer, an RV specialty center in Grants Pass, Oregon, installing MORryde’s IS system has become a common retrofit for RVers who spend a lot of time traveling the country and want a softer ride for their leaf-spring/solid-axle trailers.

Henderson’s techs enter the measurements in a MORryde computer program that informs them which specs are within MORryde’s parameters, among other info.

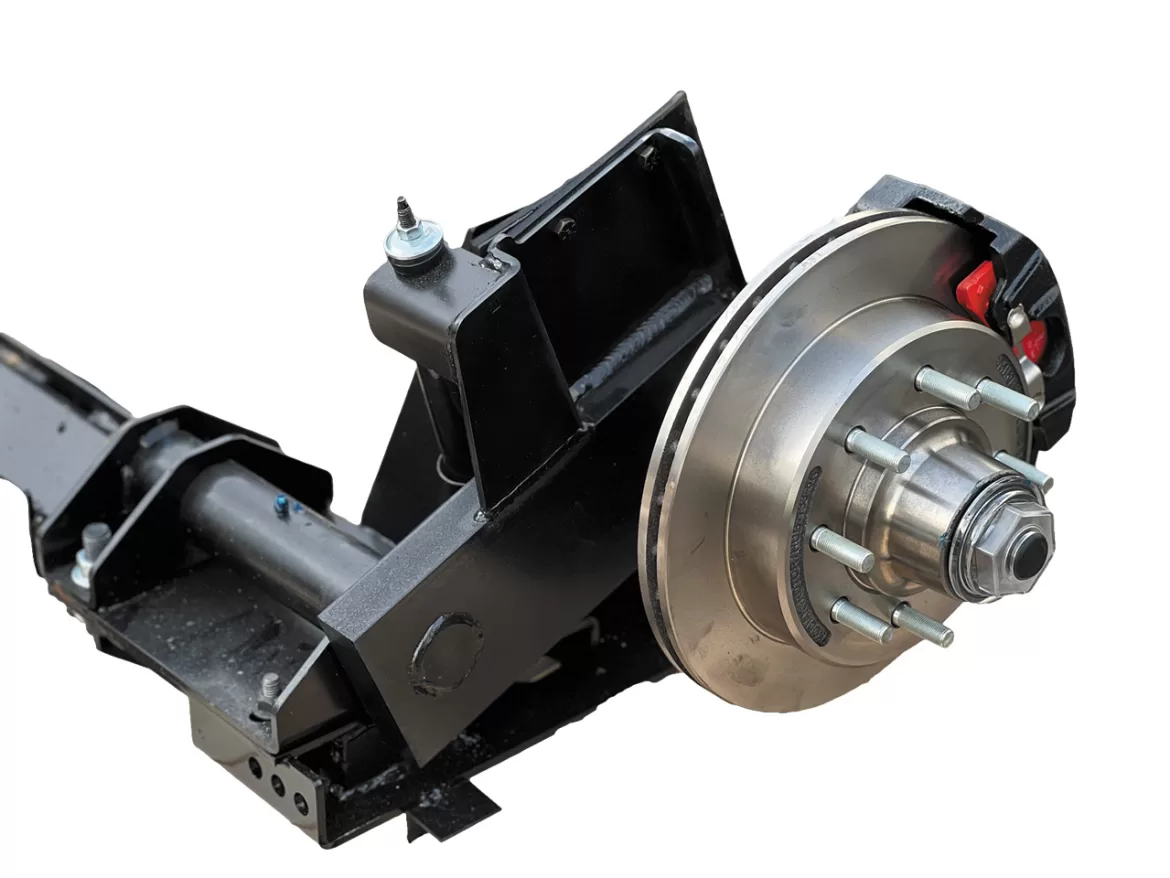

MORryde’s IS kit is both robust and simple in design. Each axle assembly consists of a heavy-duty cross tube with independent wheel assemblies attached at each end. Each side of the axle has a heavy-duty rubber shear spring between the frame and wheel mounting plates for impact absorption.

Stopping power comes via electric brakes just like those used on the original-equipment solid axles. However, MORryde offers an upgrade to a Kodiak electric-hydraulic disc brake package ($3,500), which company officials say decreases stopping distance by about 40 percent. They indicated this is the route most RVers take when having the MORryde IS system installed.

UPGRADE FOR TOY HAULERS

Both Henderson and Enfield noted that RVers toting larger tow-behind and fifth-wheel travel trailers or toy haulers will see and feel a significant improvement in ride, handling, and braking when the IS system is installed.

The original axles and springs are dropped out, spring hanger brackets removed, and frame rails prepped for the risers that each MORryde axle will be welded to.

“We see a lot of toy-hauler owners make the conversion because they’ve got their toy or toys back there sitting over 10 to 12 feet of overhang behind the rear axle. And you’ve got ATVs, side-by-sides, and motorcycles back there, and the trailer’s solid axles act almost like a springboard when the tires hit rough spots in the road. Our IS suspension diminishes those impacts to protect those toys and contents,” Enfield said.

THE COST

The MORryde conversion for a tandem-axle trailer requires about 30 hours of labor. Pricing for the IS can range from $5,000 for a two-axle IS-only installation to approximately $17,500 for a triple-axle IS with disc brakes. The price varies depending on shipping costs and local labor rates where the conversion is being done, as well as whether the owner selects the MORryde axles with the optional disc brakes. Trailers most commonly receiving the IS conversion are tandem-axle and triple-axle models with 7,000-pound to 8,000-pound leaf-spring/solid-axle setups, according to Enfield.

Installation includes welding the risers onto both sides of the trailer frame, adding a 3-by-3-inch steel tube crossmember between them, and welding the MORryde IS axles to the risers.

“The sweet spot is trailers with 7K and 8K axles,” he said. “But we can do 9,000-pound axles. We can do 6,000-pound axles. Once you get lighter than 6K, I’m not sure it makes the most sense for the return on the investment.”

The upside of such an investment is on the resale/trade-in side. Enfield said most RVers should be able to recoup a good

portion of the retrofit expense when it’s time to sell or trade in the trailer if they let the buyer or dealer know that the trailer is equipped with the MORryde IS system.

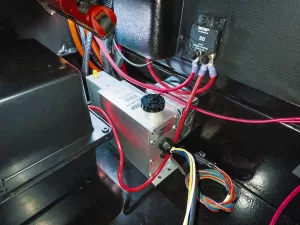

MORryde’s IS with Kodiak disc brakes requires a stand-alone trailer brake actuator. The Hydrastar HBA-16 unit uses electric signals from the brake controller in the tow vehicle to activate the new hydraulic brake system.

THE INSTALLATION

The IS conversion is time consuming and must be done by MORryde at its facility in Indiana or by one of the company’s two authorized installers: New Horizons RV in Junction City, Kansas, or Henderson’s Line-Up in Grants Pass, Oregon.

Making an appointment at any of the three conversion centers well in advance is highly recommended, because the wait time as of this writing was 10 months at MORryde’s facility, six months at New Horizons RV, and two months at Henderson’s Line-Up, Brake & RV.

The final, critical part of the conversion is wheel alignment. Henderson’s uses a Hunter Engineering DSP700 wheel alignment system to ensure a good setup.

Henderson’s Line-Up converts approximately 24 trailers a year to the MORryde IS system at its facility, so technicians are well-versed in the process. We watched them convert a Grand Design Solitude 310GK fifth-wheel travel trailer to the MORryde 7K IS and the Kodiak disc brake option. The customer pulled away a very happy family RVer.

SOURCES

MORryde

www.morryde.com

(574) 293-1581

Henderson’s Line-Up, Brake & RV

www.hendersonslineup.com

(541) 326-4033

New Horizons RV

www.horizonsrv.com

(785) 238-7575