RVers have been stuck with 1960s technology long enough.

By Gary Bunzer

February 2018

Pondering how far RV technology has come in the evolution of RVs can boggle the mind. Here are just a few examples:

- Interior lighting has progressed from propane lamps with delicate mantles to today’s cool, energy-efficient LEDs.

- Propane appliances with burners and pilot flames lit using a glow coil, zip tube, or kitchen match have been replaced by automatic electronic-ignition appliances that are fed power from the battery bank.

- Fresh-water piping that consisted of heavy, expensive copper tubing with soldered sweat fittings has given way to stronger, lightweight, cross-linked polyethylene (PEX) tubing with fittings that can be tightened by hand. And demand water pumps have been added to help deliver that water.

- As for electronics, today you can walk in the RV door, speak a com

Yes, technology has brought us to a golden age of sophisticated RVing.

So why are RV manufacturers using old technology when it comes to waste systems? Allow me to explain.

Why?

Why?

Years ago, after consumers demanded a better traveling and living experience, manufacturers equipped RVs with either a portable toilet or a recirculating toilet. Eventually, marine-type toilets became popular, and a holding tank was added at the factory. Back then, gray-water holding tanks didn’t exist; there was only a single tank dedicated to the toilet. Liquid waste bypassed the holding tank altogether at the termination assembly. It was common practice to let the sink water drain onto the ground; be captured in a portable, roll-away holding container; or be directed away from the campsite through a garden hose. In retrospect, this was quite rudimentary and unsafe.

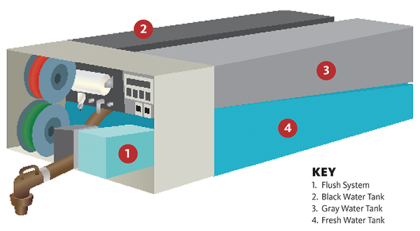

As environmental awareness grew and government oversight increased, new standards were developed, and another holding tank was added to RVs. Since then, all waste has been captured and stored in either the black-water holding tank (solid waste) or the gray-water holding tank (liquid waste). And it was at that point, back in the late 1960s, that the evolution of RV waste plumbing systems seemed to cease.

Today

Now, half a century later, RV owners still wrestle with filthy, bacteria-ridden sewer hoses that must be stored and attached by hand. (A minimum standard for such hoses has never been adopted, by the way.) RVers still must connect the RV to a questionable, ill-fitting sewer inlet somewhere. All of this happens at the risk of leakage, contamination, and disease, not to mention the miasmic ramifications.

Disgusting? Yes. Advances in electronics have made it possible for computer chips to control engines, awnings, slideouts, lighting, generators, inverters, and electrical systems, so why have there been no advances concerning the most detested aspect of RVing — proper and efficient waste control?

The fact is, waste-management technology has continued to advance. Innovations include electrically operated termination valves and improved sewer hose construction. But because of the focus on economics (justifiably so, in many cases), most RV builders have neglected to accept or adopt profound improvements across the board. There are exceptions, of course, but the vast majority of the roughly half million RVs delivered to dealers in 2017 were sold to consumers with 1960s waste-management technology aboard.

Why not?

Why do RV manufacturers shy away from such new technology? The two most apparent reasons: It would require a radical design change that would disrupt production; and it would add to the overall expense of building the RV.

These obstacles were surmounted when it came to two innovative changes that materialized over the years — basement-model floor plans and slideout rooms. Both of those advancements certainly cost more to build, and they both required design engineers to think in a new way. What’s more, RV buyers certainly have been okay with paying more for those additions.

These obstacles were surmounted when it came to two innovative changes that materialized over the years — basement-model floor plans and slideout rooms. Both of those advancements certainly cost more to build, and they both required design engineers to think in a new way. What’s more, RV buyers certainly have been okay with paying more for those additions.

Doesn’t it stand to reason that RVers also would welcome waste-plumbing technology that eliminates the most displeasing facet of RVing? Wouldn’t they want a safer, cleaner, easier method of evacuating the waste systems, even if it costs more? Many consumers contend, at the very least, such technology should be offered as a factory option. Let the RVing customer decide, but make it available.

The Upside

One possible beneficial side effect of such improvements is that manufacturers could experience fewer warranty claims. So, there is actually something in it for them as well.

The starting point in a technology upgrade is the adoption of a cam-locking method of attaching the sewer hose. The traditional bayonet fitting — whereby a circular seal is twisted against a hard ABS plastic outlet fitting to connect the hose to two or four little plastic nubs — is far surpassed by a dual-cam attachment. It involves inserting the hose straight into a female fitting with the seal ensconced inside. No twisting is necessary. The connection remains virtually leak-proof. Such technology is available in the aftermarket from Lippert Components. You just don’t see it offered by many manufacturers at the factory.

Another area is the hose itself. Lippert’s Waste Master hose features a smooth bore with exterior helical wear barriers or strength ribs. I tested the hose (see the video at https://goo.gl/46yiYy) and found it to be the toughest available. Many aftermarket competitors have adopted the new design instead of versions with a wire-bound spring embedded into thin plastic. Chances are you never will experience a leak with this new-style hose.

The New Stuff

The New Stuff

Newer waste-management design goes even further in protecting people as they empty the holding tanks. Case in point: RVers never have to wrestle with or connect an unruly, contaminated sewer hose, because the hose remains permanently attached to the waste system. The user grabs a handle equipped with a shutoff valve and extends the hose only as far as necessary to insert the nozzle into the sewer inlet. With the inclusion of an electric gate valve, the owner just opens the nozzle valve and pushes a button for each holding tank.

Such a design causes consternation for engineers because it requires them to reverse the positioning of the holding tanks, effectively flipping them end for end. But the physical mechanics of that alone should not be a cause for concern.

When the holding tanks are reversed, each tank outlet faces the passenger side of the RV. An electric gate valve is attached directly to each tank outlet, which is the optimum location for the dump valves. All utilities must be positioned at the rear of the driver’s side (street side) of the RV. Therefore, an additional “Y” fitting couples the two tank outlets and connects directly to an extra-long, flexible sewer hose that transverses the width of the coach and ultimately terminates on the street (driver’s) side. There, the hose typically is stored in a protective tube.

The Valve

With the full-flow valve on the nozzle end closed and the valves closed at each holding tank outlet, all contaminants and odors are locked inside, and the user never has to touch anything but the handle on the nozzle end of the hose. When it’s time to evacuate the tanks, the user pulls out the nozzle end as far as necessary, inserts it into the sewer inlet at the dump station or the campground sewer inlet, and then pushes a button for each tank valve to open.

Although aftermarket adaptations of this new type of waste system have been produced, ideally the chassis/frame builder would do the installation and deliver it intact to the RV builder. Or, the RV manufacturer could install it before floor construction begins.

Another plumbing unit, a plug-and-play module of sorts, also is poised to become available. The setup is designed primarily for Type A motorhomes equipped with bay doors. The ease of installing the system at the factory should please even the most reluctant design engineer. Once the unit is locked in place, it requires only connections to the upstream waste plumbing and electrical systems.

With Great Power…

So, yes, technology can be a wonderful thing, if it is utilized. It’s my guess that the first RV manufacturer to upgrade their waste management systems will have the upper hand in the retail market. Talking with RV owners, I know it would be a strong selling point. My hope is that within the next few years, consumers’ voices will be heard and a new paradigm for waste management will become a reality. Remember, RVing is more than a hobby, it’s a lifestyle!